Point Five Packaging is a rising industry leader in integrated food packaging systems and materials. Specializing in tray sealing technology, our unique Modified Atmosphere Packaging (MAP), Vacuum Skin Packaging (VSP), and Stretch Sealing solutions are designed to boost shelf life and enhance shelf appeal. Point Five sources and supplies the most advanced packaging materials to run on our equipment, delivering a one-stop shop for total concept-to-market food packaging solutions. Conveniently located in Chicago, Point Five also operates remote distribution warehouse points in New York and California.

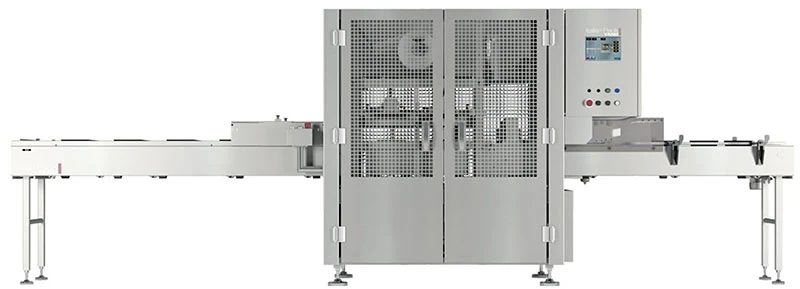

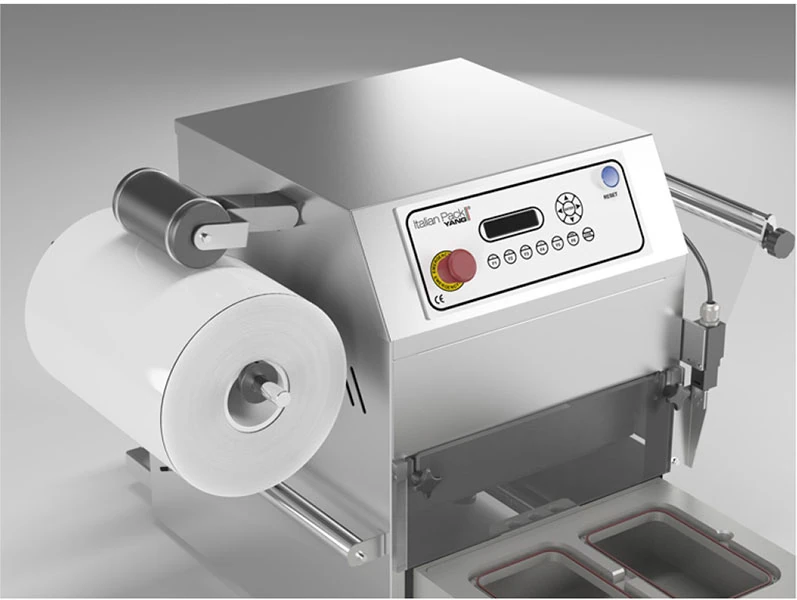

Point Five tray seal systems are manufactured by Italian Pack srl of Como, Italy but sold under our brand name in the United States and North America. We have a machine solution for any food production and packaging environment, and our systems are designed and manufactured from food-grade stainless steel and aluminum components with IP65 electrical construction. All systems are easy to operate and incorporate quick and simple product changeover for maximum flexibility.

At Point Five, we understand that keeping your system in good operating condition is crucial to the success of our working partnership. Our Chicago technical center stocks a full array of machine spare parts, and the Point Five Tech Service Group is available to provide expert start-up and training in your facility. We also offer customized preventative maintenance programs which include regularly scheduled visits, custom parts stocking, and discounted emergency labor rates, making the long-term cost of operation of a Point Five machine the best in the industry.

Building on our value-added lineup, Point Five specializes in the latest packaging materials to meet today’s market requirements. Functional, recyclable, and sustainable are all industry requirements where Point Five rises to meet the challenge as a true one-stop shop for your primary packaging needs. So whether you are working with bakery, dairy, fresh grab-n-go, frozen foods, fresh meat, poultry or seafood, ready-to-eat meals, snacks, or any other food product, Point Five is ready to deliver the solutions to your success. You’re invited to put Point Five to the test!