As many consumers are finding themselves strapped for time, food service companies are responding with smart, healthy ready-to-eat meal solutions. These pre-cooked meals can come fresh or frozen and be purchased in stores or conveniently delivered directly to consumers. Ready meals are able to offer the same nutrition, variety, and quality of food one would expect from a home-cooked meal without the consumer having to sacrifice their time to cook from scratch every day. The packaging for this type of meal needs to provide protection during shipment, be carefully sealed to prevent outside contaminants and preserve freshness, and come in microwave- or oven-safe containers for an easy reheating process.

Techhnology and Considerations for Ready-to-Eat Meal Packaging

MAP (Modified Atmosphere Packaging) extends the shelf life and preserves the freshness of all food groups without the use of preservatives or chemical additives. MAP does this by using a mixture of pure oxygen, carbon dioxide, and nitrogen to fill the food package. Hence, MAP is also known as reduced oxygen packaging.

MAP is also a cost-effective process as it saves money by preventing spoilage of products such as ready meals. It also grows the market by gaining customer loyalty through the palpable purity and improved smell and taste of packaged meals.

Vacuum Skin Packaging (VSP) can also be used to preserve the shelf life of food for ready-to-eat meals. VSP film technology is capable of confining a ready meal so that it is secured tightly, but not to the point that it would bend or cause damage to the container itself. The film and the tray are enclosed perfectly so that they are completely sealed with one another, guaranteeing a fresh and ready meal whenever it’s time to eat.

Food Packaging Materials for Ready-to-Eat Meals

Unlike packaging with a mechanical vacuum, specific materials are necessary for MAP. Some significant ones are:

The most common materials used are:

Other materials:

Food Packaging Machines for Ready-to-Eat Meals

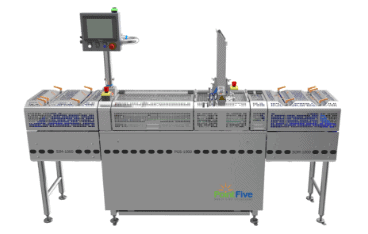

All these machines are available from Point Five Packaging, a full-service supplier of packages and packaging machinery for ready-to-eat meal companies. Since 2010, when Point Five entered the ready-to-eat meal packaging industry, it has developed a network of suppliers to deliver the latest technology and the most sophisticated packaging materials to ready-to-eat meal companies. We have a large variety of packaging materials that complement our MAP and VSP capabilities.

Some automated and manual machines used by ready-to-eat meal companies are:

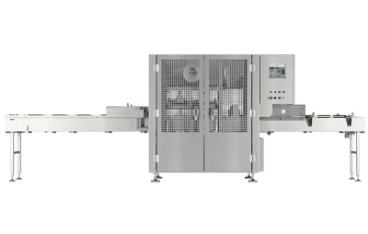

Tray & Cup Sealers for fabricating vacuum-gas flushed MAP containers and seal-only trays

Fillers/Depositors for quick and precise filling of containers

Sleeve Systems for automatic application of paperboard sleeves over cups and trays

Consumer Considerations, Dietary Concerns & Lifestyles

Ready-to-eat meals address the need of consumers for healthy and tasty home-cooked meals without the hassle of shopping for preparing ingredients. Consumers of ready-to-eat meals feel that they have the satisfaction of cooking at home while also enjoying the convenience of getting takeout, and they’re able to pre-select a menu that suits their unique dietary consumption preferences or limitations.

Many ready-to-eat meals are also custom-made and suitable for those who follow specific dietary lifestyles, including:

- Dairy-free

- Gluten-free

- Halal

- High-protein

- Keto

- Kosher

- Nut-free

- Paleo

- Vegan

- Vegetarian

Ready meal packaging needs to address the concerns of even the toughest dietary limitations by preventing these pre-cooked meals from outside contamination and still allowing for convenient features such as microwave-safe plastic or recyclable materials. These packaging features ensure the final product is a fresh, healthy, and nutritious meal that perfectly suits that individual’s needs.

Ready-to-Eat Meal Packaging Solutions from Point Five Packaging

Point Five works closely with our customers to design solutions that will fit their unique needs for package design and food content. We help our customers find smart, cost-effective solutions for all of the most popular components of ready-to-eat meals, including meat, produce, and dairy ingredients. We are also experts at improving productivity through reconfiguring factory layouts. You can request a quote from us for your specific requirements or get in touch with us to know more about Point Five.